Automatic HDPE Injection Blow Molding Machine

- Productivity:

- 100/Set

- Place of Origin:

- China

- Supply Ability:

- 100/Set

- Certificate:

- SGS

Basic Info

Model No.: JWM300

Product Description

Main features:

(1)It adopts a thermal flow system and high-pressure injection molding to get high precision of bottle mouth, bottleneck and screw. The product has no seam and leftover bits and pieces. Save raw material. And the products have the same specification and their appearance is beautiful and smooth.

(2)The injection section adopts single-screw stem horizontal injection method. The clamping molding section adopts horizontal three-work positions rotary device. It can one-mould multiple-chamber continuous production, it has high efficiency.

(3)High voltage locking mould adopts energy storing device, improve production efficiency and save energy source.

(4)It adopts auto stripping and auto flame treating and auto counting. Three sections are combined together to ensure the products not be polluted to meet the healthy demands of food and pharmacy trades.

(5)Adjust rings can be fixed in mechanical, hydraulic, air-control, electric and others to ensure the technological demands of different products.

(6)It has strong applicability to raw materials, such as PE, PP, PVC and others.

(7)The machine adopts advanced famous hydraulic and electric components. It has low-mould protection, pressure protection, flowing adjustment and other functions. It has hand-operated, semi-auto and auto operation.

(8)The production efficiency of the machine is high. Its noise is low and its power consumption is small, the operation is safe and convenient. It is an ideal equipment to produce package bottles for pharmacy, food and other trades.

JWM equipment improvement

1. New designment of deck plate & beam decreases deformation and optimizes pressure distribution when mold clamping.

2. Optimizing safety door, give consideration to usability and security.

3. New designment of Rotary box system is more durable, easier to maintain, higher & more stable rotating speed. Moreover it overcomes old type the defect of shake rotating & easy wearing.

4. Optimizing hydraulic system with completely design of open mold & close mold oil-way, that increase mold open & close speed, and no leakage when mold clamping long; Rotary cylinder & lifting cylinder add quick/slow switching, functions speed higher and stable.

5. Replaced high quality air valve, gas circuit simple and easy to maintain.

6. Blow institution of patent tower: Integral cast iron turret, mechanical prepare institution, save prepare time & exhaust time, optimizing core rod cooling, improving connected precision of mold, reducing maintain cost.

7. Optimizing equipment circuit, oil pipe setting short and sweet, changing oil pipe type, withstand pressure, difficult to leakage.

8. Cylinder inner structure improved, adding thicker seals to reduce oil cylinder leakage. Adding cooling plate for Injection mold opening & closing cylinder, improved the problem of mold high temperature transmit quicken seals aged.

9. Adding label, diagram form etc. Hommization setting, improved equipment usability.

In short: Retaining the basic of equipment function, habitual operating, JWM improves equipment reliability, hommization and working efficiency. Same mold working efficiency is improved, cycle time obviously quicker.

(actual measurement cycle time is about 3 seconds when JWM300 empty operating, and no need prepare time, exhaust time, decompression time any more when put material producing)

Injection blow molding machine parameters:

Model | JWM300 | |

Injection system | ||

Screw diameter | mm | 40 |

Screw L/D |

| 22:1 |

Injection weight | cm3 | 200 |

Clamping system | ||

Clamping force of injection | KN | 300 |

Clamping force of blowing | KN | 46 |

Table lift height | mm | 65 |

Dry cycles | s | 3.2 |

Mould | ||

Max. Platen size(L*W) | mm | 400*270 |

Mold thickness | mm | 180 |

Suitable bottle dimension | ml | 5-800 |

Bottle height | mm | ≤200 |

Dia. Of bottle | mm | ≤100 |

Stripping stroke | mm | ≤220 |

Driving system | ||

Hydraulic pressure | Mpa | 15 |

Total power | kW | 25 |

Motor power | kW | 15 |

Heating capacity | kW | 8.3 |

Others | ||

Min. Air pressure | Mpa | 1 |

Air volume | m3/min | ≥0.6 |

Water consumption | m3/h | 3 |

Dimension(L*W*H) | M | 3.4*1.2*2 |

Net weight | T | 4 |

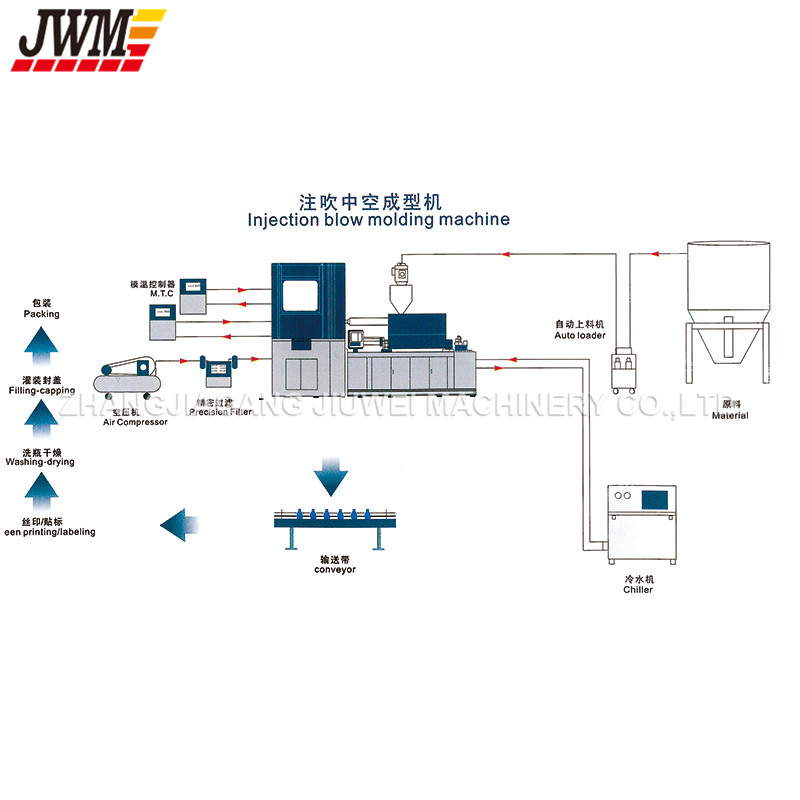

Injection blow molding machine components of main parts:

Injection blow molding machine components of main parts: No. | Main parts | Supplier | |

1 | HYDRAULIC VLAVE | YUKEN, TAIWAN | |

2 | HYDRULIC MOTOR | INTERMOT, ITALY | |

3 | PNEUMATIC VALVE | FESTO, GERMANY | |

4 | HYDRAULIC PIPE | ISR, CHINA | |

5 | SEAL RING | DZ, TAIWAN | |

6 | AC CONTACTOR | SCHNEIDER, CHINA | |

7 | HYDRAULIC PUMP | Piston Pump | YUKEN, JAPAN |

8 | Control system and hand screen(supply options) | JINHUA, TAIWAN | |

Product Categories : Injection Blow Molding Machine 300

Premium Related Products