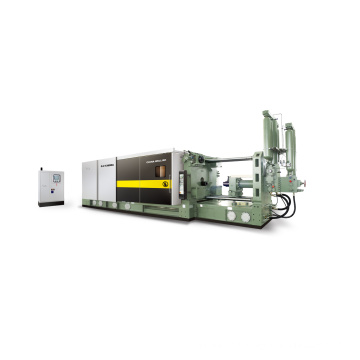

Cold Chamber Die Casting Machine C/300d

- Productivity:

- 500PCS/Year

- Place of Origin:

- Ningbo China

- Supply Ability:

- 500PCS/Year

- Certificate:

- CE, RoHS, SGS, GS, ISO9001

Basic Info

Model No.: C/300D

Product Description

Model NO.: C/300D Condition: New Certification: CE, RoHS, SGS, GS, ISO9001 Trademark: ALLWAY Specification: CE, SGS, ISO9001: 2008, CQC HS Code: 8454301000 Control Type: PLC Automatic Grade: Automatic Type: Special Casting Transport Package: Standard Packing Origin: Ningbo China Specifications

1.cold Chamber Die Casting Machine.

2.IS09001:2000 Certification and CE Safety Certification

Strategy

The goal of manufacturing famous products and developing the company for centuries has been passed on from generation to generation. In past 20 years, we always provide perfect cold/ hot chamber Die Casting Machine and sincere service.

* With a history of over 20 years * Factory Area : 20,000 square meters

*Employees : More than 200 *Production Capacity : 1,000-sets yearly capacity

*Company owed Tech & Research center * Main Machines: 50sets

SCAN:

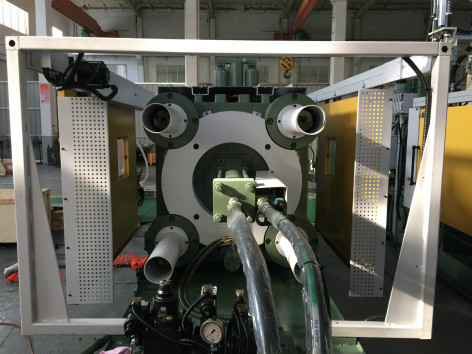

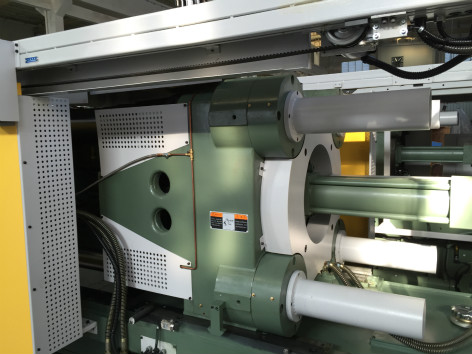

1.300T Cold die Casting Machine

2.Suitable for aluminum,zinc and copper alloy

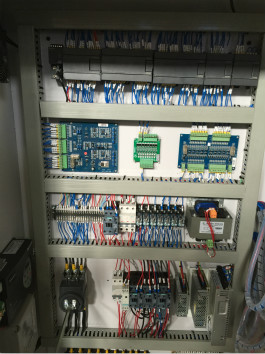

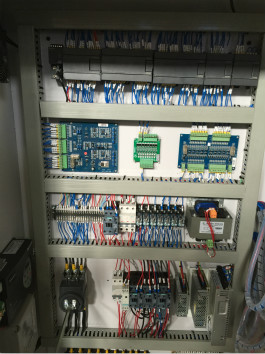

3.PLC and person-machine

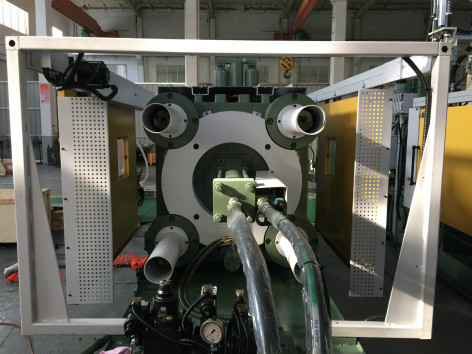

4.4-rod pilot elastic framework for excellent rigidity

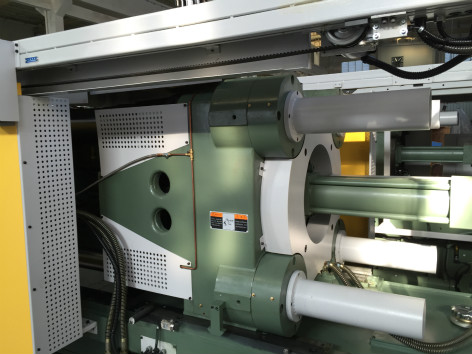

5.Proportional relief and flow control valves

6.PLC and person-machine interface

What product this machine can make? ----- The cold chamber die casting machine is suitable for die casting of non-ferrous metal with low melting point, such as aluminum, zinc and copper. It is widely applied for die casting of fittings of automobile and motorcycle, and parts for instrument and meter, and household appliance hardware of daily necessities.Deals with the research and manufacturing of high precision die casting machines for many years(start from 1995). With "WELLISH"brand cold chamber series(140-2080Tons), hot chamber series(30-200Tons), MG ALLOY series(140-1380Tons). Frequency translation&servo drive saving-energy system techology, with high quanlity moulds and furnace and auxiliary machines provide AL/MG/Copper/Zinc Alloy prodct solutions for you.

Contact us if you need more details on Die Casting Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Casting Machine、Cold Chamber Die Casting Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

1.cold Chamber Die Casting Machine.

2.IS09001:2000 Certification and CE Safety Certification

Strategy

The goal of manufacturing famous products and developing the company for centuries has been passed on from generation to generation. In past 20 years, we always provide perfect cold/ hot chamber Die Casting Machine and sincere service.

* With a history of over 20 years * Factory Area : 20,000 square meters

*Employees : More than 200 *Production Capacity : 1,000-sets yearly capacity

*Company owed Tech & Research center * Main Machines: 50sets

SCAN:

1.300T Cold die Casting Machine

2.Suitable for aluminum,zinc and copper alloy

3.PLC and person-machine

4.4-rod pilot elastic framework for excellent rigidity

5.Proportional relief and flow control valves

6.PLC and person-machine interface

What product this machine can make? ----- The cold chamber die casting machine is suitable for die casting of non-ferrous metal with low melting point, such as aluminum, zinc and copper. It is widely applied for die casting of fittings of automobile and motorcycle, and parts for instrument and meter, and household appliance hardware of daily necessities.Deals with the research and manufacturing of high precision die casting machines for many years(start from 1995). With "WELLISH"brand cold chamber series(140-2080Tons), hot chamber series(30-200Tons), MG ALLOY series(140-1380Tons). Frequency translation&servo drive saving-energy system techology, with high quanlity moulds and furnace and auxiliary machines provide AL/MG/Copper/Zinc Alloy prodct solutions for you.

| Specification | C/300D | |

| Clamping Force | KN | 3000 |

| Clamping Stroke | mm | 480 |

| Die-Thickness (Min-Max) | mm | 250-680 |

| Platen Size(H*V) | mm | 900x900 |

| Space between Tie-Bars | mm | 580x580 |

| Diameter of Bars | mm | 110 |

| Casting Force | KN | 142-340 |

| Casing Stroke | mm | 440 |

| Injection Plunger diameter | mm | 50 60 70 |

| Max. Casting Volume (AL) | kg | 1.6 2.2 3.1 |

| Max. Casting Volume(MG) | kg | 1 1.5 2 |

| Casting Pressure (Min-Max) | Mpa | 72.3-173 50-120 36.9-88.3 |

| Cast Projection Area | Cm2 | 162-759 |

| Injection Position | mm | 0, -160 |

| Ejector Space | mm | 150 |

| Extruding Flange Diameter | mm | 110 |

| Height of Extruding Flange Pattern | mm | 12 |

| Ejecting Force | KN | 180 |

| Ejecting Stroke | mm | 105 |

| Dry Cycle Time | s | 8 |

| System Working Pressure | Mpa | 16 |

| Motor Power | KW | 18.5 |

| Tank Capacity | L | 850 |

| Machine Weight | kg | 12500 |

Product Categories : Die Casting Machine

Premium Related Products

Other Products

Hot Products

MH-55T-1S new sliding working table vertical plastic led injection machineMHW-55T TR90 material for glasses vertical/Horizontal plastic injection molding machine,sole machineLSR servo and automatic plastic injection machines manufacturersChina New 120tons Vertical Clamping Horizontal Plastic sole Injection Molding MachineHigh Speed Injection Molding MachineSmall Injection Molding MachineGood Price Energy Saving Injection Molding Machine 128ton with CeJwm600 Injection Blow Molding MachineInjection Blow Molding Machine (JWM450)PE/PP/HDPE/LDPE Plastic Bottles Injection Blow Molding MachineHigh Pressure Die Cast Die for Auto Parts/Die Casting MouldHigh Efficiency Energy Saving Press Machine/ Punch Machine (APA-200)Cold Chamber Die Casting Machine for Metal Castings Manufacturing C/200d780ton High Efficiency Energy Saving Injection Molding Machine (AL-UJ/780C)Plastic Cap Injection Molding MachineHigh Speed Pet Prefrom Injection Molding Machine with Servo System